Carbon Air Filter Filtration Separation

$61.461-19 Piece/Pieces

$58.39≥20Piece/Pieces

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Port: | Shenzhen |

$61.461-19 Piece/Pieces

$58.39≥20Piece/Pieces

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Port: | Shenzhen |

Model No.: YF-B010

Brand: YUKA

Origin: China

Element Serve Life: 6000~8000 Hours

Trademark: Yuka

HS Code: 8421399090

Clapboard: Without Clapboard

Filter Number: 1

Medium Material: Fiberglass

Type: Cartridge Filter

Material: Aluminum Alloy

Housing Serve Lige: 15 Years

Filtration Performance: From 5 μm To 0.01μm

Operate Temperature: 1.5~80ºc

Resistance Corrosion: Inside And Outside

Transport Package: Brown Inner Box & Cardboard

Efficiency: F5

Filtration Grade: Medium Filter

Connection: Rc1/2"

Flow Rate: 1.0 M³/Min

Maxi. Operate Pressure: 1.6 Mpa

Filtration Efficiency: 99.99%

Element Material: Sodium Borosilicate Glass Fiber

Belong To: Air Compressor System

Color: Light Blue

Specification: Dimension: 96 X 79x 245mm

| Selling Units | : | Piece/Pieces |

| Package Type | : | Carbon |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

YUKA YF-B series Compressed Air Filter is design for 16 bar working pressure condition which could fit work for many kinds air compressor.

Which is recommended for the industries in general automation equipment, pneumatic tools,printing, film production, laser cutting and nitrogen generator.

Seven Grades Filter Element

PF AO AA AX ACS AR AAR As a primary filter, particles whose diameter more than 5μm can be remove,the maxi. residual oil content is negligible

As a primary filter, particles whose diameter more than 5μm can be remove,the maxi. residual oil content is negligible

High effiency oil remove filtration, dust particles, water mist and oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.01mg/m³(21ºC),0.01ppm(w)

Ultra-efficient filtration, dust particles, water mist&oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.001mg/m³(21ºC),0.001ppm(w)

Dust particles whose diameter more than 0.01μm, oil vapor &odor can be removed, the maxi. resident content of oil vapor does not exceed 0.003mg/m³(21ºC),0.003ppm(w)

Dust particles whose diameter more than 1μm can be removed

Dust particles whose diameter more than 0.01μm can be removed

Product are test with the international advanced testing equipment based on standard ISO12500, Which is equivalent to the standard ISO8573.1-2010 quality standard, and provide filter performance test report.

Filtration Grade

PF

AO

AA

AX

ACS

AR

AAR

Size of solid particles(ISO12500-3)

5μm

1μm

0.01μm 0.01μm - 1μm 0.01μm Filtration performance of solid particles(ISO12500-3)

- 99.999+%

99.999+%

99.999+%

99.999+%

99.999+%

99.999+%

Filtration performance of oil(ISO12500-1)

50%

80+%

99.9+% 99.9+%

- - - Residual oil content(ISO12500-1)

5mg/m³

0.6mg/m³ <0.01mg/m³ 0.001mg/m³ <0.004mg/m³ - -

For application in other working pressure, please refer to the correction factors.

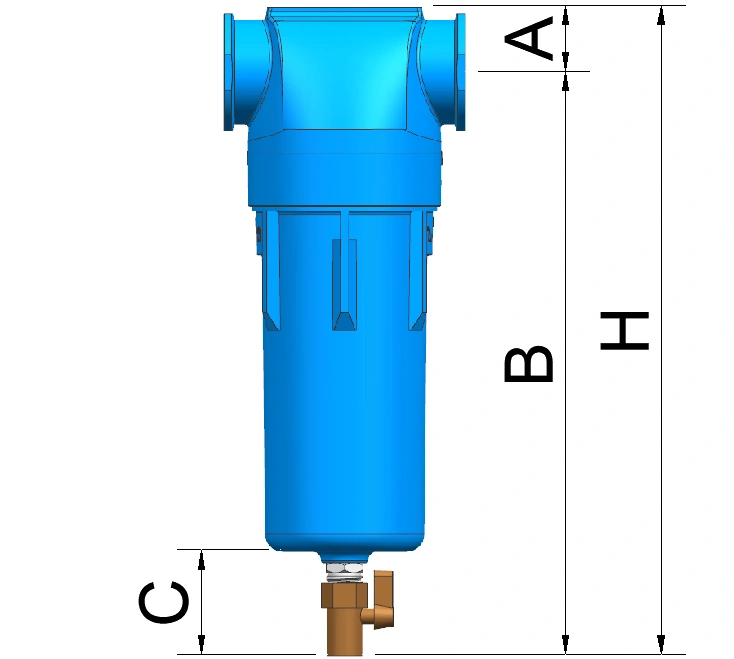

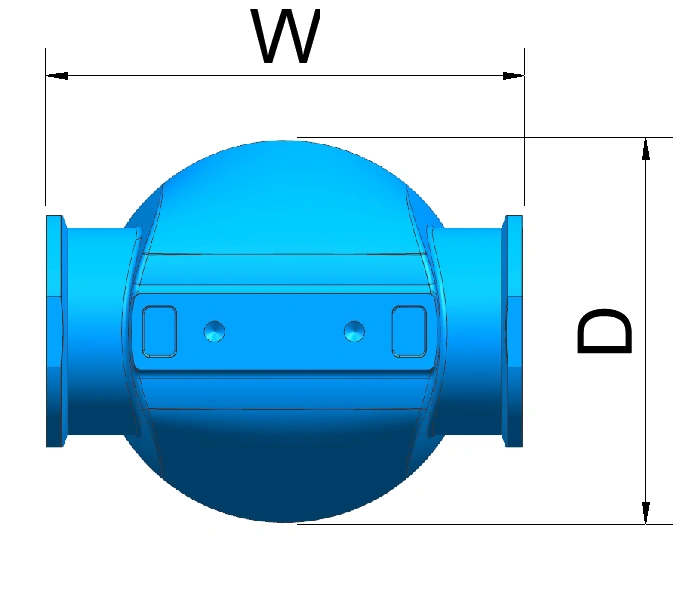

| Model | Pipe size | Flow rates | Dimension (mm) | |||||||

| L/S | m³/min | scfm | W(Width) | D(Depth) | H(Height) | A | B | C(clearance for housing) | ||

| YF-B010 | RC1/2" | 16.7 | 1.0 | 35.5 | 96 | 79 | 245 | 29 | 180 | 118 |

| YF-B020 | RC3/4" | 25.0 | 1.5 | 53.0 | 96 | 79 | 245 | 29 | 180 | 118 |

| YF-B030 | RC3/4" | 30.0 | 1.8 | 63.6 | 96 | 79 | 274 | 29 | 209 | 153 |

| YF-B040 | RC1" | 33.3 | 2.0 | 71.0 | 96 | 79 | 274 | 29 | 209 | 153 |

| YF-B060 | RC1" | 60.0 | 3.6 | 127.0 | 138 | 111 | 349 | 37 | 276 | 208 |

| YF-B070 | RC1" | 83.3 | 5.0 | 177.0 | 138 | 111 | 450 | 37 | 377 | 303 |

| YF-B080 | RC1-1/2" | 125.0 | 7.5 | 265.0 | 138 | 111 | 450 | 37 | 377 | 303 |

| YF-B090 | RC2" | 166.7 | 10.0 | 353.1 | 174 | 142 | 558 | 58 | 500 | 467 |

| YF-B100 | RC2-1/2" | 216.7 | 13.0 | 459.0 | 174 | 142 | 558 | 58 | 500 | 467 |

| YF-B110 | RC2" | 283.3 | 17.0 | 600.0 | 174 | 142 | 838 | 58 | 780 | 794 |

| YF-B120 | RC2-1/2" | 316.7 | 19.0 | 671.0 | 174 | 142 | 838 | 58 | 780 | 794 |

| YF-B130 | RC3" | 416.7 | 25.0 | 883.0 | 220 | 184 | 616 | 74 | 542 | 514 |

| YF-B140 | RC4" | 466.7 | 28.0 | 989.0 | 220 | 184 | 616 | 74 | 542 | 514 |

| YF-B150 | RC3" | 683.3 | 41.0 | 1448.0 | 220 | 184 | 892 | 74 | 798 | 764 |

| YF-B160 | RC4" | 800.0 | 48.0 | 1695.0 | 220 | 184 | 892 | 74 | 798 | 764 |

| Technical requirements | Maximum operating pressure: 16 barg Maximum operating temperature: 80°C Minimum operating temperature:1.5°C | |||||||||

| Pressure | Barg | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Psig | 15 | 29 | 44 | 59 | 73 | 87 | 100 | 116 | 131 | 145 | 160 | 174 | 189 | 203 | 219 | 232 | |

| Correction factor | 0.38 | 0.53 | 0.65 | 0.76 | 0.85 | 0.93 | 1.00 | 1.07 | 1.13 | 1.19 | 1.23 | 1.31 | 1.36 | 1.41 | 1.46 | 1.51 | |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.