Top Quality Coalescing Air Filter

$999.541-19 Piece/Pieces

$949.56≥20Piece/Pieces

| Payment Type: | L/C,T/T |

| Incoterm: | EXW,CIF,CFR,FOB |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Shanghai |

$999.541-19 Piece/Pieces

$949.56≥20Piece/Pieces

| Payment Type: | L/C,T/T |

| Incoterm: | EXW,CIF,CFR,FOB |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Shanghai |

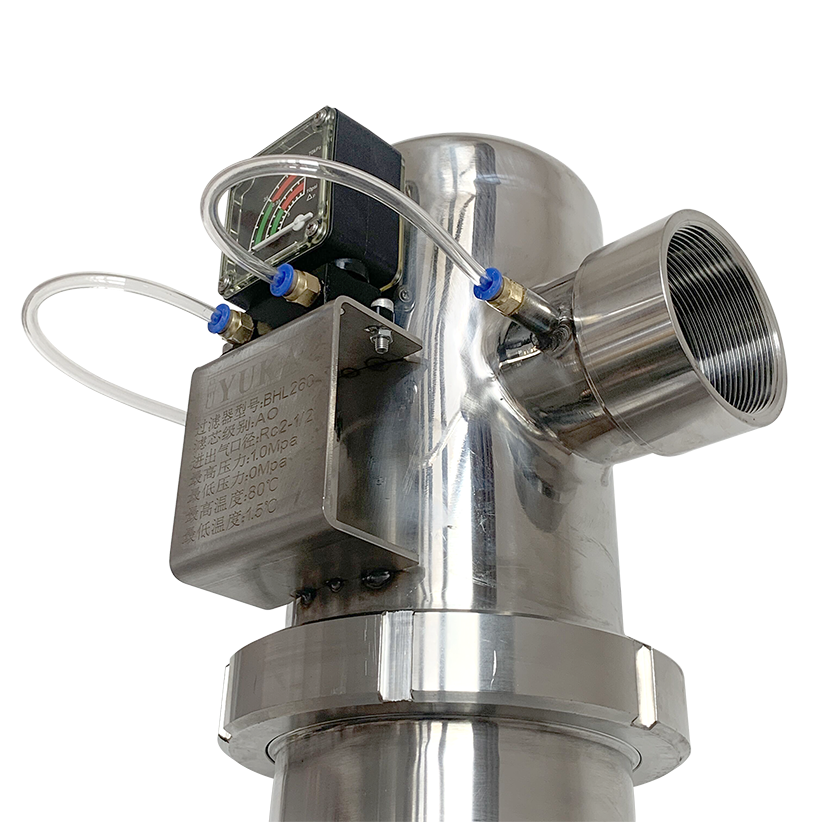

Model No.: BHL330

Brand: YUKA

Place Of Origin: China

Filter Case Material: Stainless Steel 304 Or 316 For Options

Assembly Type: Tri-Clamp

Filter Element Top & End Cap: Stainless Steel

Maxi. Working Pressure: 16 Bar G

Working Temperature: 1.5℃ To 80 ℃

Screw Tpye: Socket Rc Type

Applied For: Food & Beverage & Medical Industries

Flow Rate: 15 M³/Min

Connection Size: Dn65

Leakage Tested: 100% In Three Times

| Selling Units | : | Piece/Pieces |

| Package Type | : | Carton |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

How Does A Coalescing Filter Work?

When you’re working with air compressors, air purification and filtration is an critical part of maintenance. Compressed air filters play an important role in your industrial air compressor system. Choosing the right filter not only increases the efficiency of your unit, but it can also reduce energy costs and protect your employees from harmful chemicals and particulates.

However, does all air filter work for your compressed air system? Well it is depending on your working conditions, the project you’re completing and how often you use your equipment, you’ll need to make an precise choice. This guide will detail how air compressor filters work, why they’re important, what type of air compressor filter to buy and when you should replace it.

A. Air compressor filter does is keep water, oil and dirt from down to your pneumatic tools, making them essential to the overall health of your air system. These kinds of dust or particles can damage or destroy your equipment if you don’t offer proper filtration. If they pass through those tools, your project will be affect in negatively, such as by destroying a paint job or contaminating foods in production facilities.

One of the benefits of air filters is that they are reasonable investments. What you have to keep up with wear and replace them in time, it costs far less to purchase new filters than to pay for repair costs for damaged pneumatic equipment or air compressors. You’ll receive result in positive, as keeping the air that passes through your compressor clean is critical to tool and equipment health as well as work quality.

B.Compressed air systems require clean air to function properly and provide air to applications that does not damage machinery. Properly functioning air filters consist of pre-filters and after filters:

Pre-filters: These filters trap and filter the wet, dirty air that enters the air dryer.

After filters: These filters then filter the dry air as it leaves the dryer.

Particulate filters capture debris, oils and other coarse contaminants. The air then enters the coalescing filter, which gets rid of fine impurities like water or oil aerosols. After the air leaves the dryer, it goes through another particulate filter to make sure the air is totally clean.

Feature & Advantage

· 304 & 314 stainless steel material in die-casted integrated technology, housing warranty with 15 years.

· Design for harsh and complex working environment, low maintenance and repaired fee.

· Stainless steel filter element material, double support mesh, prevent second pollution from itself.

· Filtration performance meet ISO8573.1-2010 standard, particle removal accuracy down to 1 micron.

Technical Specification

| Model | Connection | Flow rate | Dimension(mm) | ||||

| L/S | m³/min | scfm | Width (W) | Depth (D) | Height (H) | ||

| BHL030 | 25 | 25.1 | 1.5 | 53.0 | 150.0 | φ76 | 250 |

| BHL080 | 40 | 66.8 | 4.0 | 141.2 | 170.0 | φ108 | 390 |

| BHL145 | 40 | 116.9 | 7.0 | 247.1 | 170.0 | φ108 | 530 |

| BHL220 | DN65 | 183.7 | 11.0 | 388.3 | 220.0 | φ133 | 700 |

| BHL260-330 | DN80 | 250.5 | 15.0 | 529.5 | 320.0 | φ133 | 980 |

| BHL360 | 334.0 | 20.0 | 706.0 | ||||

| BHL430 | DN80 | 450.9 | 27.0 | 953.1 | 360.0 | φ159 | 850 |

| BHL620 | DN100 | 467.6 | 28.0 | 988.4 | 360.0 | φ159 | 1080 |

| BHL800 | DN100 | 835.0 | 50.0 | 1765.0 | 420.0 | φ219 | 1180 |

| BHL1000 | DN125 | 1002.0 | 60.0 | 2118.0 | 473.0 | φ273 | 1203 |

| BHL1200 | DN125 | 1336.0 | 80.0 | 2824.0 | 473.0 | φ273 | 1203 |

| BHL1400 | DN150 | 1670.0 | 100.0 | 3530.0 | 530.0 | φ325 | 1280 |

| BHL1600 | DN150 | 2505.0 | 150.0 | 5295.0 | 580.0 | φ377 | 1350 |

| BHL1800 | DN200 | 3340.0 | 200.0 | 7060.0 | 630.0 | φ426 | 1450 |

| BHL2000 | DN200 | 4175.0 | 250.0 | 8825.0 | |||

| BHL2200 | DN250 | 5010.0 | 300.0 | 10590.0 | 720.0 | φ500 | 1550 |

| BHL2400 | DN250 | 5845.0 | 350.0 | 12355.0 | |||

| Technical Requirement: | Maxi.pressure:16barg, Maxi.working temperature:80℃, Mini working Temperature: 1.5℃ | ||||||

Pressure Barg 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Psig 15 29 44 59 73 87 100 116 131 145 160 174 189 203 219 232 Correction factor 0.38 0.53 0.65 0.76 0.85 0.93 1.00 1.07 1.13 1.19 1.23 1.31 1.36 1.41 1.46 1.51

Filter Element Grade

Filtration Grade PF AO AA AX ACS AR AAR Size of solid particles(ISO12500-3) 5μm 1μm 0.01μm 0.01μm - 1μm 0.01μm Filtration performance of solid particles(ISO12500-3) - 99.999+% 99.999+% 99.999+% 99.999+% 99.999+% 99.999+% Filtration performance of oil(ISO12500-1) 50% 80+% 99.9+% 99.99+% - - - Residual oil content(ISO12500-1) 5mg/m³ 0.6mg/m³ <0.01mg/m³ <0.001mg/m³ <0.004mg/m³ - -

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.